Recent Trends and Future of Pharmaceutical Packaging

The need to keep medicinal products safe and free from all possible contaminations has led to many advancements in the field of pharmaceutics, primarily in packaging operations. Innovations in packaging protocols have resulted in custom-built pharmaceutical packaging solutions that keep pharmaceutical compounds unadulterated.

Pharmaceutical experts have always strived to develop adaptable casings and compliant packaging modules, with little success in the past. However, now continuous efforts to produce better medication compliance packaging solutions have led to top-grade packing articles, such as blow-fill-seal (BFS) vials, pre-filled syringes, snap-off ampoules, plasma impulse chemical vapour deposition (PICVD) coating technology, unit-dose containers, two-in-one vials, methadone lockbox among many others.

Considering the continuous developments in pharmaceutical packaging, it’s only fair to say that medicinal packing will become even more conducive to keeping the integrity of medicines intact. The efficiency and reliability of the Pharmaceutical Supply Chain play a crucial role in this progress. It is vital to review the recent trends to better understand the future of pharmaceutical packaging.

Pharmaceutical Packaging

Pharmaceutical packaging refers to the science of developing an array of wrapping articles to hold medicines from the point of production to their use.

Objectives of Pharmaceutical Packaging

The main objectives of packing pharmaceutical products are

- Containment: naturally, the first goal of a packing component is to hold a medicinal compound,

- Protection: Next is to keep medicines and other therapeutic items free from foreign elements to prevent contamination.

- Information: to provide details of medicinal chemistry for users

- Identification: to exhibit information about the manufacturer.

- Convenience: to contain dosage-based volumes of medicines for convenient administering

Based on the functions mentioned above, pharmaceutical packaging continues to undergo developments for improved products.

Categories of Pharmaceutical Packaging

Generally, packaging operations/products are divided into three categories based on the function of particular packing components. Meaning, depending on what a container holds, it is classified into one of the following groups.

- Primary packaging systems: materials that directly come in contact with a medicinal compound as they hold the actual therapeutic amalgam.

- Secondary packaging systems: include containers that keep all primary packing systems together, such as cartons, boxes etc.

- Tertiary packaging systems: include holdings that carry secondary packing containers for bulk storage and distribution, such as barrels, containers.

Containers Used Currently

While there are many pharmaceutical materials used currently, these are known to have transformed the packing game.

Blow-Filled-Seal Vials

BFS vials are a common packing component in modern-day pharmaceutical packaging. They are formed in a streamlined process in which plastic moulds are created, filled with medicinal products and sealed without interruption. This method keeps the therapeutic compounds free of contamination and minimizes personnel involvement.

Anti-Counterfeiting Packing Technology

As surprising as it may seem, counterfeit medicines are readily available in the market, putting users/patients at risk. To deal with the malign practice of selling counterfeited products, field experts have devised different techniques to enable users to distinguish between faux and authentic medicine.

There are a bunch of tactics used to achieve that, including

- Highlighting primary features: Typically, medicines have elements that are expensive and not easy to acquire, which only licensed manufacturers can get. These features are overtly displayed on pharmaceutical packages to verify the authenticity of the product inside.

- Sealing containers: Sealing bottles and tubes ensures that users know whether an item is genuine or not because if the seal is broken, they’ll know that the medicine’s integrity has been compromised.

- Using breakable caps: as the name suggests, breakable caps are impenetrable unless punctured. This way, a patient can know if a bottle has been tampered with if the top is not intact.

RFID- Radio Frequency Identification

It is an advanced technology that uses radio frequencies to identify products. It has three components responsible for wireless communication; the tag, the reader and the software.

The tag is an electrical circuit with an electronic product code, a trackable pin to identify a product. This code is transferred via electromagnetic waves within the radio ecosystem. The reader then reads the oncoming signal and sends it to the software for identification.

RFID reduces if not eliminates the chances of counterfeiting medicines, keeping the medicinal integrity intact and authenticity reliable.

Aside from the mentioned packaging systems, pre-filled syringes, dosage-unit vials etc., are used to administer the correct volume of medicine to the patient much more conveniently.

The Future OF Pharmaceutical Packaging

As clear from the present packing practices, pharmaceutical professionals want to develop containers and storage units to make pharmaceutical traceability much easier.

Furthermore, future packaging systems will be focused on dosage management to make drug compliance easier for patients. With materials containing only the recommended volume of a compound, users will be able to better manage their drug consumption.

Additionally, dual-chamber packaging is likely to gain popularity in the upcoming times as it allows patients to manage multi-drug administration conveniently.

Simply put, packaging that allows effective pharmaceutical traceability, user engagement and ensures their convenience will probably receive traction in the future.

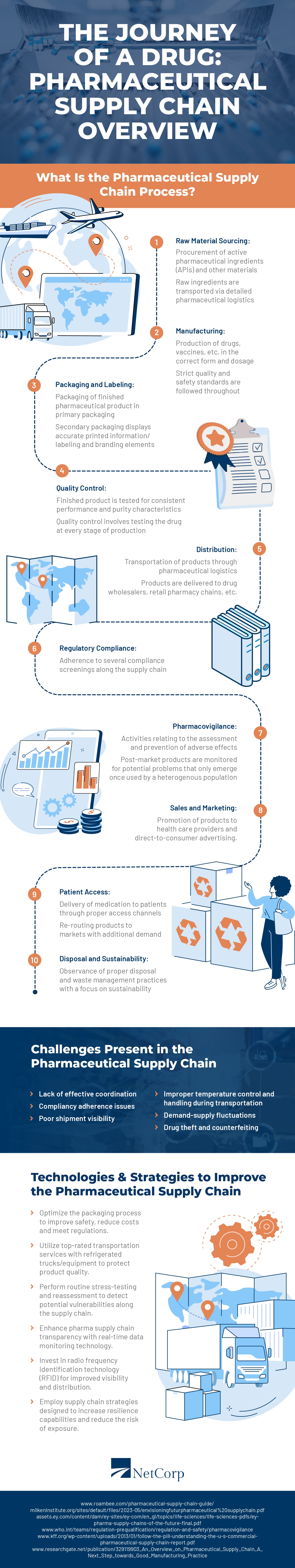

To learn about the journey of a drug through through the pharmaceutical supply chain please see the infographic below.

Provided by trailer rental and sales company, NetCorp